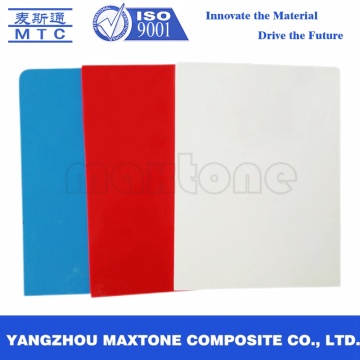

Frp Gel-coated Panels FRP Panel FRP flat sheets

| Min. Order: | 200 Square Meter |

|---|

| Packaging: | Packed by Steel Pallets or Steel Frames |

|---|---|

| Productivity: | 800, 000m²/Year |

| Brand: | MAXTONE |

| Transportation: | Ocean,Land,Air,Express |

| Place of Origin: | Yangzhou, China |

| Supply Ability: | 1,600, 000m²/Year |

| Certificate: | IS0: 9001 Quality Certificate |

| HS Code: | 3921909090 |

| Port: | SHANGHAI,NINGBO |

Basic Info

Model No.: MTCGSH-010

Click on the follow link to find out more information: https://www.maxtonetruckbody.com/glossy-frp-sheet/

Company Info

- Company Name: YANGZHOU MAXTONE COMPOSITE CO.,LTD.

- Representative: Guo Jiang Chen

- Product/Service: FRP Panel , Refrigerated Truck Body , Dry Freight Truck Body , FRP Sandwich Panel , Caravan Body , Van Body

- Capital (Million US $): US$ 5 Million

- Year Established: 1996

- Total Annual Sales Volume (Million US $): US$10 Million - US$50 Million

- Export Percentage: 21% - 30%

- Total Annual Purchase Volume (Million US $): US$10 Million - US$50 Million

- No. of Production Lines: 10

- No. of R&D Staff: 21 -30 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 50,000-100,000 square meters

- Factory Location: 7#Xinyi Road

- Contact Person: Mr. Oliver Lee

- Tel: +86-0514-82060713

Premium Related Products

Other Products

Hot Products

BBQ Grill Mats Grill Pad Barbecue Bakeware Pad Baking MatWPC Wall Panel WPC Decking Wood Plastic Composite DeckingKevlar Fiber Fabrics Products Aramid FabricWPC Wood Plastic Composite DeckingPVC Foam, 60kg/M3 PVC Foam, 80kg/M3 PVC Foam, 130kg/M3 PVC Foam, 200kg/M3 PVC FoamFiberglass Fiberglass Mat Fibergalss Mulaxial Fabrics Fiberglass Fabric Direct Roving Multi-End Roving Spray up Rovingexport superior heat resistant ptfe seamless fusing machine beltsProfessional manufacturer High-Temperature Resistant PTFE Open Mesh Dryer Conveyor BeltGood tensile strength Teflon/ptfe fusing beltsBlack teflon /PTFE coated fiberglass fabricFiberglass Mesh Fabric Fusing Machine PTFE Fiberglass Mesh Conveyor Beltshigh quality barbecue material Teflon/ptfe BBQ grill matheat resistant and flame retardant silicone coated fiberglass fabricNon-stick Oven Liner,easy cleaning, reusable, High temperature resistant.anti static high quality heat resistant ptfe coated adhesivetapeartisan non-stick silicone baking mat - 2 pack