Multilayer Metal Core PCB

Product Description

JHYPCB is an expert Multilayer Metal Core PCB ("Multi Layer MCPCB" for short) manufacturer, which provides its customers with the best quality Multi Layer MCPCB, and Double Sided Metal Core PCB. These 2 layer Metal Core PCB are used in mission-critical applications across various industries.

What is Multi Layers MCPCB?

Just like FR4 PCB, we can also make boards with more than 2 layers of traces and we named it "Multi Layers MCPCB". The structure is similar with FR4 Multi Layers, but it much more complex to make.

Compared with normal FR4, this sturcture need more technology and experience on laminating of more than two layers together with metal core and the cost is much higher than 2 layers MCPCB or double sided MCPCB.

You can populated more components on the boards, put signal and ground layer into seperated layers, to achieve better performance in electrical performance.

Metal core PCBs are classified into different types based on the number of trace layers and the location of the metal core. Two (Double) layers metal core printed circuit boards have two layers of copper conductor on one side of the metal core. A two layer metal core printed circuit board requires an extra step to laminate the metal core and imaged thermal conductive laminate.

What is Multi Layers PCBs?

Multi-layer PCBs are printed circuit boards, which comprise of more than two copper layers like 4L, 6L, 8L, etc. The multilayer PCBs are compact sized, and offer benefits of weight and space. Due to these benefits, the multilayer core PCBs are used in various aerospace, as well as mission-critical military applications. JHYPCB provides consistent quality multilayer, impedance controlled, and HDI PCBs in various specifications. We provide these circuit boards at fastest turnaround times, and assured low prices than Others.

Advantages of Multilayer PCBs

The multilayer PCBs provide several advantages over single layer PCBs, which makes them popular across various industries. Few of the advantages are as follows:

High Assembly Density:

Multilayer PCBs have high assembly density than single layer PCBs, which help us build compact PCB packages. These circuit boards reduce the need for interconnection wiring harnesses.

High Flexibility:

These PCBs feature two or more layers, which are stacked together with a mutual connection between them. There are three conductive layers in any single multilayer PCB – with two layers on the outer side, and one layer in the board. This construction allows high flexibility. Also, this construction allows easier impedance control.

Low EMI Shielding:

The EMI shielding in these circuits are lowered through the careful organization of ground, as well as power layers.

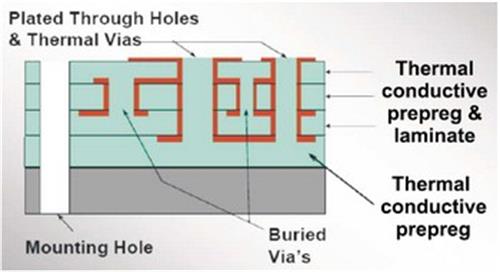

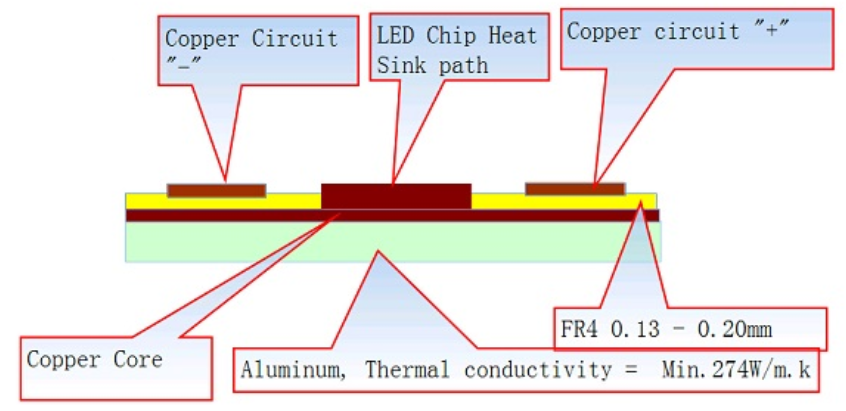

Structure of Multilayer Metal Core PCB

Advantages of Two (Double) Layers Metal Core PCBs

There are a lot many advantages of using two layers metal core PCBs. Some of the key advantages include:

- Longer Component Life

- High Heat Dissipation

- Good Dimensional Stability

- High Watt Density

Applications of Two (Double) Layer MCPCBs

These circuit boards have a number of advantages, because of which they find their use in a wide range of applications. Some of the applications of double layer MCPCBs are:

- Office automation equipment

- Power modules such as power rectifier relays, inverters, etc.

- Audio equipment such as balanced amplifiers, preamplifiers, etc.

- Power controllers and electronic regulators in automobiles

- Communication electronic equipment such as transmitter circuits, and high frequency amplifiers

Capabilities of Multilayer Metal Core PCB

We are very particular when it comes to manufacturing Double Sided Metal Core PCB. This has helped us manufacture best quality metal core printed circuit boards. We are known to provide fast turnaround times, which guarantees you quick delivery.

We provide our customers with Multi Layers MCPCB of following capabilities:

| Base material | Aluminum/Copper/Iron Alloy |

| Thermal Conductivity (dielectrial layer) | 0.8, 1.5, 2.0, 3.0 W/m.K. |

| Board Thickness | 0.8mm~3.0mm(0.02"~0.12") |

| Copper thickness | 0.5 OZ, 1.0 OZ, 2.0 OZ, 3.0 OZ |

| Outline | Routing, punching, V-Cut |

| Soldermask | White/Black/Blue/Green/Red Oil |

| Legend/Silkscreen Color | Black/White |

| Surface finishing | Immersion Gold, HASL, OSP |

| Max Panel size | 600*500mm(23.62"*19.68") |

| Packing | Vacuum/Plastic bag |

| Samples L/T | 15~18 Days |

| MP L/T | 15~20 Days |

Metal Core PCB material

Metal Core PCB material including Aluminum PCB,Copper Base PCB, Iron base PCB. Aluminum is popular in the market special in LED lights market because of Cost .

Metal Core PCB means the core (base) material for PCB is the metal, not the normal FR4/CEM1-3, etc. and currently the most common metal used for MCPCB manufacturer are Aluminum, Copper and steel alloy. Aluminum has good heat transferring and dissipation ability, but yet relatively cheaper; copper has even better performance but relatively more expensive, and steel can be divided into normal steel and stainless steel. It more rigid than both aluminum and copper, but thermal conductivity is lower than them too. People will choose their own base/core material according to their different application.

Metal Core PCB material: Aluminum PCB

Aluminum PCB , also,it is called Aluminium PCB,metal core PCB,mcpcb, IMS(Insulated metal substracte).

Aluminum PCB have 3 parts:

1.Circuit Layer (Copper Layer)

This is printed circuit copper foil layer, From 1.0 oz up to 8 oz (35um-280um). Min.Trace/space 5/5mil(0.127/0.127mm)

2.Dielectric Layer(Insulated Layer)

There are very good price and delivery time if the raw material made in China and Taiwan, we also,have many customer who choose Bergquist Thermal-Clad and Larid Tlam material,strict meet customer`s Requirement to manufacture the ALPCB.

3.Substrate Layer(Metal layer)

There are 4 types Aluminum, 1001, 3001, 5052, 6063. If no requirement of this from,we used 5052 for High thermal conductivity (2.0 W/m.k or more) , AL1001,AL3001 for 1.0 w/m.k to 1.5 W/m.k

Aluminum Clad PCBs

Available as 1 layer Non-Plated Through Hole (single sided), And 2+ layer Plated through Hole. Ideal application for LED lighting, power supply solutions. Aluminium Clad Benefits Include:

- Lower operating temperature.

- Reduce printed circuit board size.

- Increase power density.

- Extend the life of dies.

- Reduce the number of interconnects.

- Improve product thermal and mechanical performance.

- Combine power and control.

- Improve product durability.

- Enable better use of surface mount technology.

- Expedite heat sinks and other mounting hardware.

- Replace fragile ceramic substrates with greater mechanical durability

About Price:

1. PCB thickness: 0.6 – 3.0mm, always thickness more ,price higher

2. Thermal conductivity: 1.0 – 10 W/m.k , thermal conductivity higher, price higher

3. Material factory: Bergquist, Laird ETC, made in US factory that is more expensive than China.

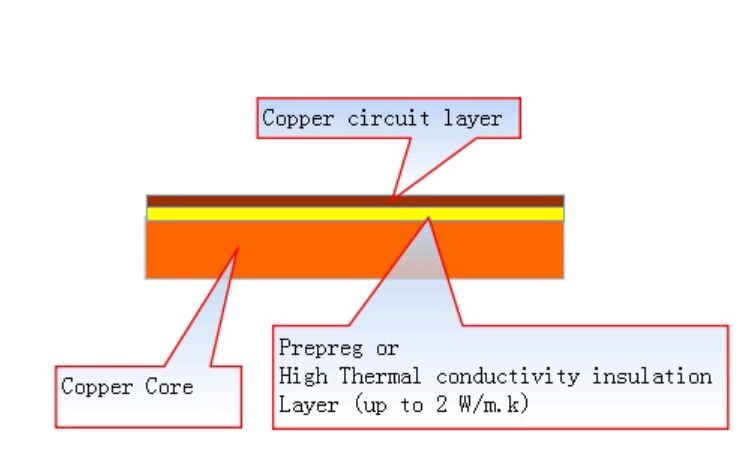

Copper core PCB is a copper substrate + Insulated layer + copper

Copper core PCB is a copper substrate + Insulated layer + copper circuits layer PCB,also, it is called copper substrate pcb, copper based pcb,copper clad pcb.

As a MCPCB manufacturer,we made various Copper core PCB for customers,

Which used for High Power LED lighter ( 1000W+ ) and power supply.

In LED field,there are 4 types of Copper based Circuit Board.

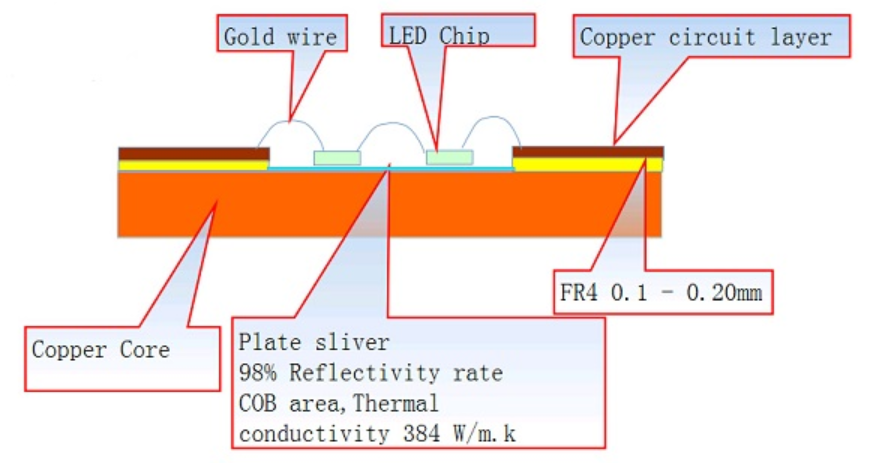

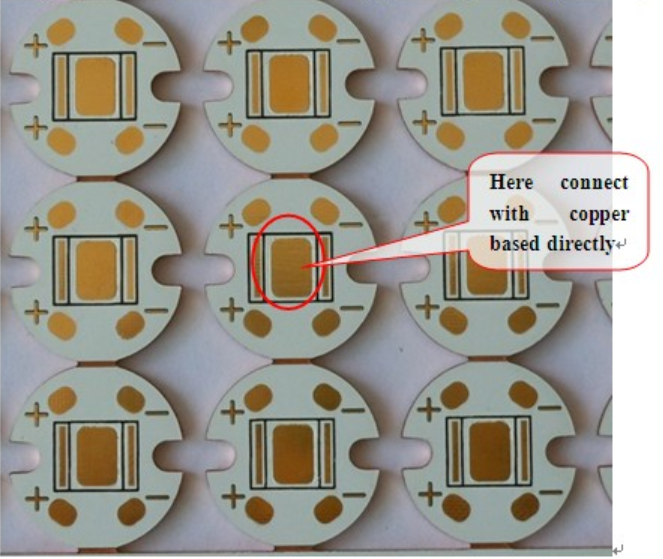

2. COB Copper PCB(Chip on Board copper PCB)

LED chip Direct thermal sink to copper substrate.

3. Direct thermal path,no dielectric layer under the thermal path pad.

4.Direct thermal path,no dielectric layer,Aluminum-copper pcb.

The third One : Iron Based PCB

The iron-based PCB use material for the base is from special steel, silicon steel and ect in stand of FR4 or CEM1 and can dissipate heat away from critical board components and to less crucial areas such as metallic core or the metal heatsink backing.

China PCB manufacturers becomes more and more professional on Iron-Based PCB.

The Iron-based PCB has all the functions as metal materical and the following particular characteristics:

①Vacancy area convenient for further machinery , procuring and fixing of the base ;

②High mechanic strength,good forther machinery suitable for the assembly heaven electronic parts on its surface;

③Silicon-steel is iron magnetic, and can be applied on micro-motors such as on VTR,FDD.

Helpful Resources

4 Layer PCB

6 Layer PCB

8 Layer PCB

10 Layer PCB

12 Layer PCB

Product Categories : Metal Core PCB